Controlling the air: how are automation systems arranged?

At the present stage, mechanisms and systems for regulating ventilation modes are widely available for sale: from ordinary thermostats to complex computerized systems. This contributes to the solution of any automation tasks at facilities, with the exception of the human factor in the coordination and control of ventilation systems.

Each object is specific, and if standard modules are suitable for controlling simple systems, then for complex and large-scale ones (with a mass of devices and equipment of different groups), an automation system will turn out due to system assembly manually and 100% personally.

About the complete set of the ventilation automation system The automation

modules are divided into 3 nodal groups: The

operation of the fans is controlled by sensors mounted inside the room and redirecting information about the characteristics of the environment:

- temperature conditions;

- air humidity;

- the state of the gas environment;

- clean air.

After measurements, the data is redirected from the controllers to the coordination center, where the received information is collected and analyzed. After analyzing microclimatic factors, the center gives an order, if necessary, to ventilate the room or, having responded to an emergency situation and, having detected a fire, will block the inflow of fresh air masses (in order to avoid further spread of fire).

In addition to coordinating bodies, the automated system is equipped with executive units (servo drives that regulate the location of valves, frequency converters that control the speed of rotation of the fan, etc.) that carry out the operations of the mechanisms.

Based on the specifics of each option, one of the three modes of functioning of the automated system is used:

- fully automatic: all automated system components are combined into coordination by all engineering systems of the facility;

- autonomous: the automation and ventilation system is not coordinated with other processes inside the facility;

- manual: control and coordination is carried out by the operator; innovative automated systems are equipped with a remote access function (the operator adjusts the settings while away from the object.

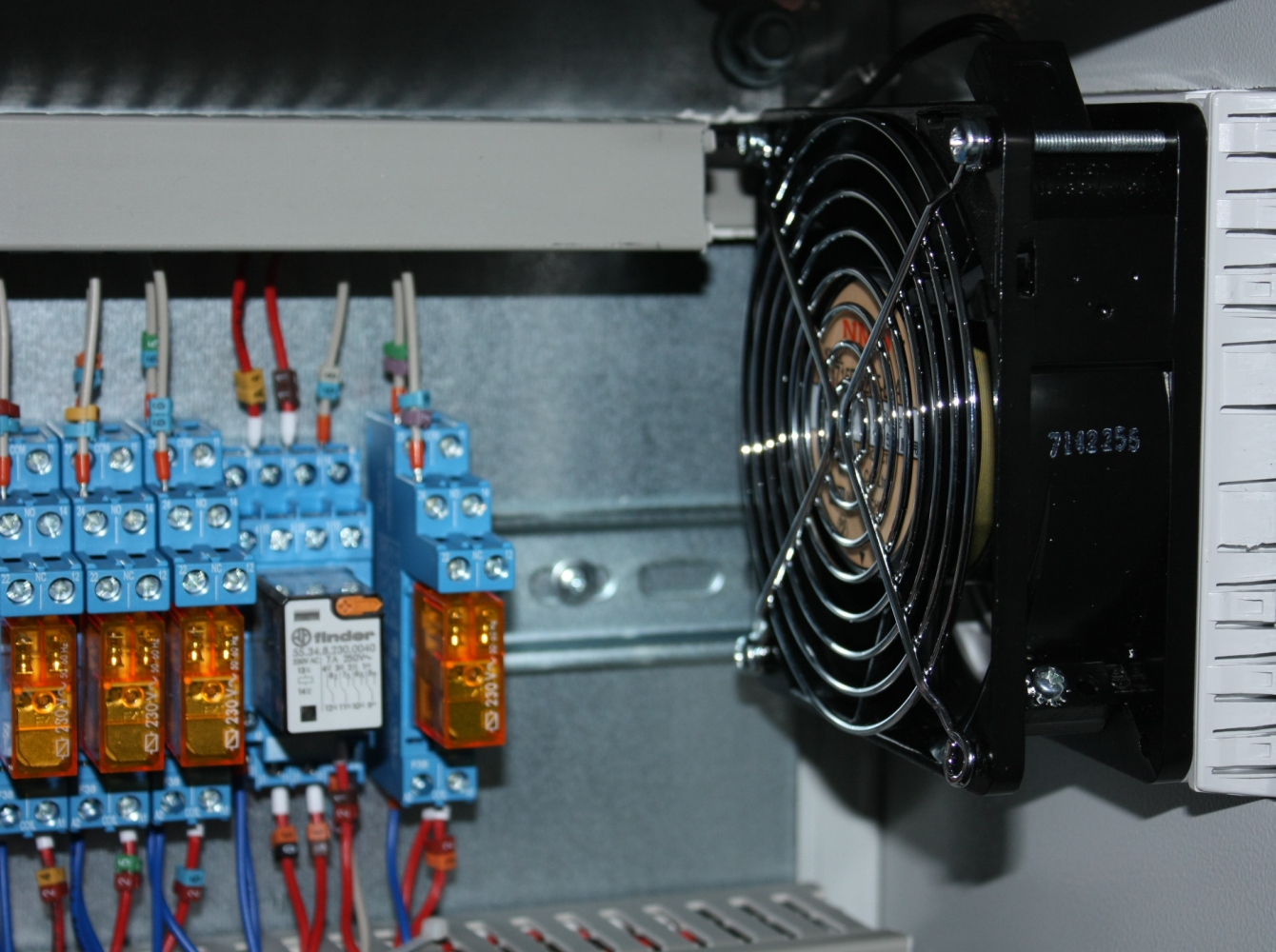

Automation panels

They are needed when the object is oversaturated with a large number of networks and when devices for measuring microclimate parameters are located in hard-to-reach places (for example, in ventilation shafts or in wall niches) In such a situation, the data from the devices are redirected to the ventilation control panel, which is a panel with control devices and indicators.Functions of

automated panels:

- control of ventilation equipment;

- protection against overheating and short circuit or erroneous installation;

- adjustment of the power and productivity of ventilation equipment;

- installation of operating modes systems or devices for a specific period of time (day, week, month)

Order

remotely with one click